ANNEX

Case study "Folding Attic Stairway"

Case study - "Folding attic stairway"

1. The plaintiff, a company from Galway in Ireland, and the defendant, a Welsh company, manufacture, sell and install folding attic stairways in houses. It is common ground that the attic stairways manufactured and sold by the plaintiff and the defendant have the same constructional features.

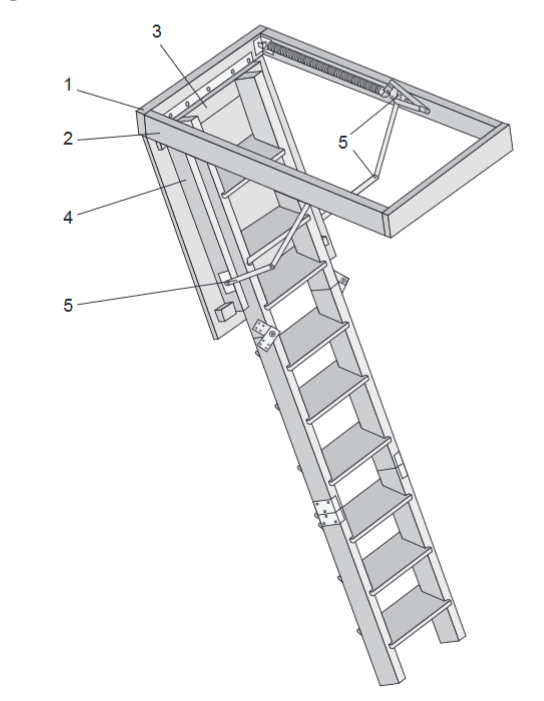

2. On 5 November 1996, the plaintiff applied to the UK Intellectual Property Office to patent a process for manufacturing its attic stairway. The claims, description and drawings of the patent granted on 30 August 2000 are identical to those of the patent application published on 13 May 1998. The embodiment of the stairway manufactured and sold by the plaintiff is illustrated below:

1 end member of the outer frame

2 side member of the outer frame

3 end beam (end member) of the inner frame

4 side beam (side member) of the inner frame

5 foldable support arm with pivots

3. The plaintiff had been manufacturing, selling and installing folding attic stairways long before 1996. The previous model differed from the stairway manufactured according to the patent in particular in that the support arms were attached underneath directly to the sides of the ladder stairway and not to the side beams of an inner frame onto which the ladder is mounted. In 1995, during checks of the plaintiff's records with a view to ISO certification, it was found that customers sometimes complained that the support-arm pivots stopped working properly or even broke. This fault occurred if there was a big difference between the width of the ceiling opening and the width of the ladder, and if the stairway was used often or by heavy individuals.

4. The plaintiff sued the defendant for infringing its patent.

5. The defendant countersued for revocation, claiming that the patent was invalid, because

5.1 Its subject-matter was not novel:

Firstly, during ISO certification the Irish Minister for Trade and Tourism had visited the plaintiff's factory, accompanied by a newspaper reporter. A popular local newspaper had published a photograph showing the minister on the shop loor with a folded-out prototype of the attic stairway - installed there most probably for test purposes - visible in the background.

Secondly, ladders in accordance with the manufacturing process developed by the plaintiff had already been installed in at least three houses before the patent application was filed.

5.2 But even if the stairway according to the patent was regarded as novel, it was not inventive over the prior art, i.e. the attic stairways previously manufactured and sold by the plaintiff, with support arms attached directly to the side beams of the extendable ladder and not to an inner frame, which was mounted at a "preset" distance from the outer frame. It was an oddjob man's development to the previous model, based only on experience and requiring no technical expertise. Any talented "do-it-yourselfer" could build such a stairway.

6. Regarding the claim for revocation, the plaintiff countered that neither the newspaper photograph nor the stairway's installation in three houses had destroyed the novelty of its manufacturing process.

6.1 The photo showed the minister in close-up, whereas only the vague outlines of the prototype were discernible in the background. Not even its construction was clear; still less, from the blurred image in the photograph, could any knowledge be gained, or conclusions drawn, about the manufacturing process.

6.2 The stairways manufactured according to the teaching of the patent had been installed, exclusively by the plaintiff's own long-serving and loyal staff, in three terraced houses occupied by pensioner couples. The residents were laymen who would not have been able to deduce the determining features of the manufacturing process from the stairways installed.

6.3 The manufacturing process according to the patent did indeed involve an inventive step:

Firstly, the problem with the previous model had not been obvious to the skilled person, because most of these ladders functioned for a long time

with no problems. Only under specific conditions did the support-arm pivots become unable over time to bear the strain, i.e. if the support arms had to be bent considerably to bridge the difference between the width of the ceiling opening and the width of the ladder, and if a stairway with more or less bent support arms was used very often or by heavy individuals. The inventor had realised that bending the support arms strained their pivots, and that the more the support arms were bent, the weaker the stairway became. The solution according to the patent was to construct the stairway in such a way that the support arms required little or no bending.

This not only solved the non-obvious technical problem of overstrained pivots; it also led to considerable cost savings for both manufacturer and customer, because the use of a weight-bearing inner frame mounted at such a distance from the outer frame that the support arms connecting the two frames required little or no bending enabled the attic stairways to be fitted with standard ladders. In other words, for ceiling openings of various widths, it was always possible to use a ladder of the same width or select one of two or three different standard widths.

The manufacturing process was efficient and cost-effective, because essentially only the length of the end (cross-) members of the outer frame had to be adapted to the width of the ceiling opening in which the stairway was to be installed. Similarly, with the inner frame, only the end members needed to be adapted to the dimensions of the outer frame. All side members could be standardised.

Last but not least, it had to be borne in mind that the patent was for the manufacturing process, so it was not about an individual product, but rather the problem of efficiently and cost-effectively manufacturing and installing a substantial number of these products for ceiling openings of various widths.

7. Regarding the action for infringement, the defendant contended that even if the plaintiff's patent was considered valid he had not infringed its claim 1 by manufacturing and selling ladders of the same construction.

7.1 According to claim 1, the outer mounting frames had to be made to the dimensions of a "ceiling ope[ning] of a predetermined size". But he as defendant did not specify that size, and therefore did not implement that feature.

7.2 In particular, he did not implement the feature "such that each side beam [of the inner frame] is spaced a preset distance inwardly of the side members of the outer frame". Here it was unclear by whom the distance was preset, and according to what criteria.

The plaintiff was arguing that the distance chosen had to be such that the support-arm pivots were not unduly stressed by bending. But he neither mentioned that in the claim nor gave a measurement for "undue" stress.

He (the defendant) had not chosen the distance between the outer and inner frames of his stairways on the basis of stress on the support-arm pivots. His own objective had been to adapt the distance between the two side beams of the inner frame to the width of his standard ladders.

That the attic stairways he manufactured, for ceiling openings of various widths, had similar distances between the side beams of the inner and outer frames to those of the plaintiff's was a coincidence and due to the fact that his company aimed to use its widest standard ladder possible for a given width of ceiling opening, to ensure comfortable use for its customers.

8. The plaintiff was unimpressed by these arguments. For many years, before and after 1996, the defendant had sold and installed, in England and Wales, the ladders that he (the plaintiff) had manufactured. Due to their previously close business relationship the defendant had been aware of the problems with the attic stairways' old construction - and also, therefore, of the reasons for the patented solution.

Questions:

1. Has publication of the photo of the minister standing in front of the prototype stairway, or the stairways' installation in three terraced houses, destroyed the novelty of the stairway according to the patent?

2. Does the manufacturing process according to the patent involve an inventive step?

3. Has the defendant infringed the patent by manufacturing, selling and installing attic stairways with the same construction as those manufactured according to the patented process?

4. Could the infringement action (also) succeed on the basis of claim 6?

Please answer all questions. When answering questions 2, 3 and 4, assume that you answered the preceding one on the basis that the patent was valid.